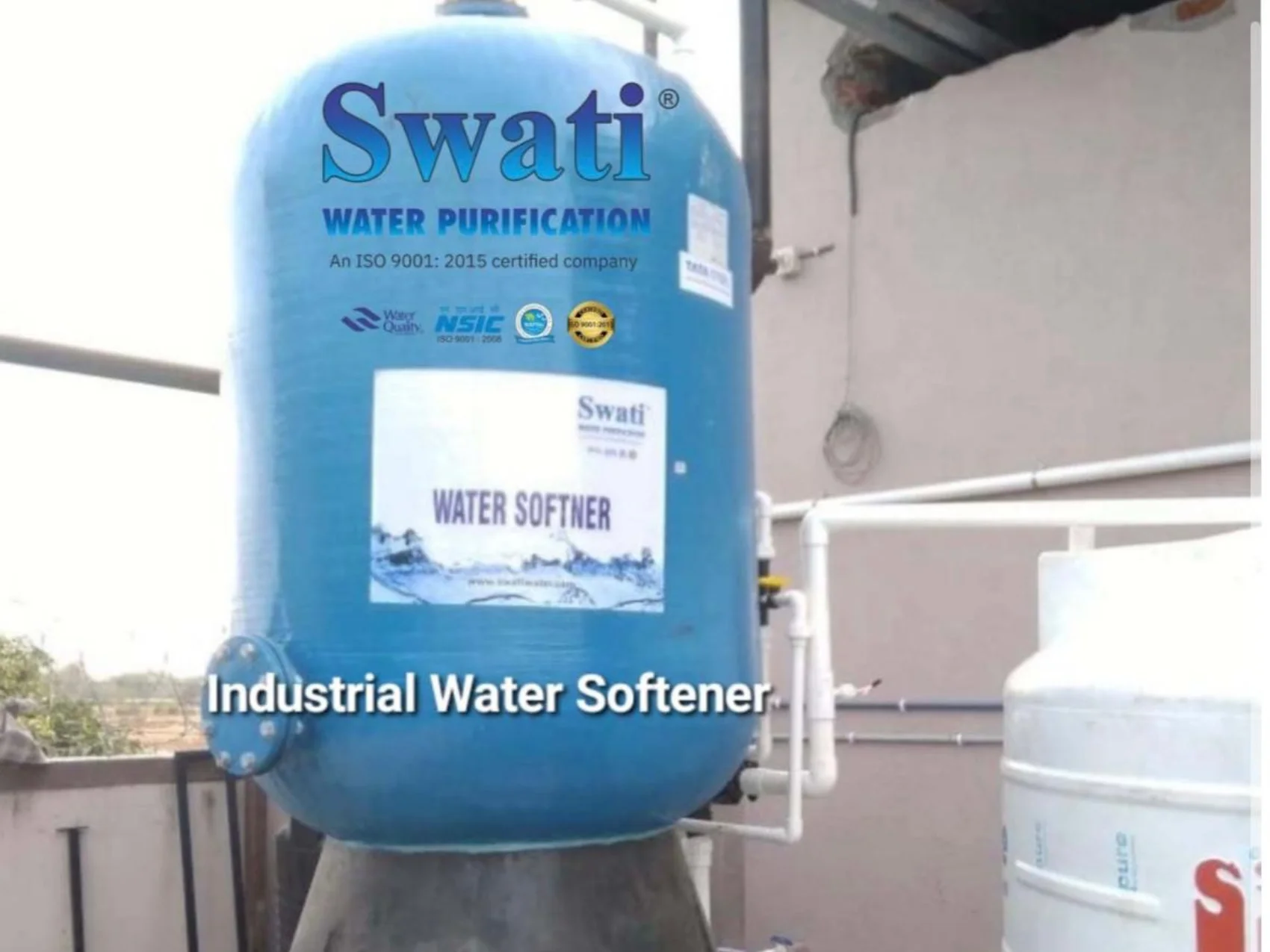

Cooling Tower Water Softener System

Swati Water Purification – Cooling Tower Water Softener System Supplier, Cooling Tower Water Softener System Manufacturer.

Cooling Tower Water Softener System

A Cooling Tower Water Softener System is an integral part of water treatment in industries and commercial facilities that use cooling towers to dissipate heat from their processes. Similar to boiler

water softeners, cooling tower water softener systems are designed to soften water by removing hardness-causing minerals such as calcium (Ca2+) and magnesium (Mg2+) ions. By softening the water, these systems help prevent the formation of scale and fouling in cooling tower equipment, thus improving efficiency, extending equipment life, and reducing maintenance costs.

Cooling Tower Water Softener Systems also known as, “Cooling Tower Softener,” “Industrial Water Softener,” “Water Softening System For Cooling Towers,” “Ion Exchange Softener,” “Boiler Water Softener,” “Reverse Osmosis Softener,” “Dual Tank Water Softener,” “Cooling Water Treatment Softener.”

We Are Manufacturers & Suppliers In Ahmedabad, Gandhinagar, Gujarat, India, Sanand GIDC, Mehsana, Vitthalapur, Mandal Bechraji Special Investment Region(MBSIR), Halol GIDC, Bavla Kerala GIDC, Dahej SIR & PCPIR(Petroleum, Chemicals and Petrochemicals Investment Region), Dholera SIR, GIDC Industrial Area(Gujarat Industrial Development Corporation), MIDC Industrial Area(Maharashtra Industrial Development Corporation), MPIDC Industrial Area(Madhya Pradesh Industrial Development Corporation), RIICO Industrial Area(Rajasthan State Industrial Development & Investment Corporation), PSIDC(Punjab State Industrial Development Corporation), SEZs Area(Special Economic Zones), SEEZ Area(Solar Energy Enterprises Zone) In Rajasthan, Peenya Industrial Area In Bengaluru(Bengalore, Karnataka). It Removes Hard Water Minerals from Water and Replaces Them with Softer Minerals. It Consisits Of a Mineral Tank, Brine Tank and Other Components.

Capacities

- Small-Scale: 5 to 50 KLD (e.g., small industrial units or commercial buildings).

- Medium-Scale: 50 to 500 KLD (e.g., medium-sized factories or commercial establishments).

- Large-Scale: 500 to 5,000 KLD (e.g., large industrial plants, power plants)

The Capacity Depends on Factors like Water Hardness, Cooling tower size and specific industrial needs.

Materials We Used: FRP, LLDP, MS, MSEP, MS Rubber Lining and Stainless Steel

How to Work:

1. Ion Exchange: Water flows through a resin bed that exchanges calcium and magnesium ions with sodium ions, softening the water.

2. Regeneration: Once the resin becomes saturated with hardness minerals, a brine solution (high in sodium) is passed through the resin to restore its ability to soften water.

3. Softened Water: The treated, softened water is then sent to the cooling tower, where it prevents scale formation on cooling surfaces and improves heat transfer efficiency.

This process helps protect the cooling tower equipment and maintain efficient operations.

Applications Of Cooling Tower Water Softener Systems In Different Industries:

1. Industrial Plants: Prevents scaling and corrosion in cooling systems, ensuring efficient heat exchange.

2. Power Stations: Softens water to protect cooling towers and heat exchangers.

3. Refineries: Ensures smooth operation of cooling systems by reducing mineral buildup.

4. Manufacturing: Protects cooling equipment and improves operational efficiency in factories.

5. Chemical Plants: Reduces scale formation in cooling towers, improving process reliability.

6. Chemical Manufacturing: Prevent Scale formation on heat exchangers and cooling systems that are sensitive to hard water.

7. Food & Beverage Industry: Cooling towers in the food & beverage sector often use softened water to avoid scale build-up, especially in processes where water quality is important for product consistency.

These systems are essential in improving efficiency, reducing maintenance and extending the lifespan of

cooling equipment.