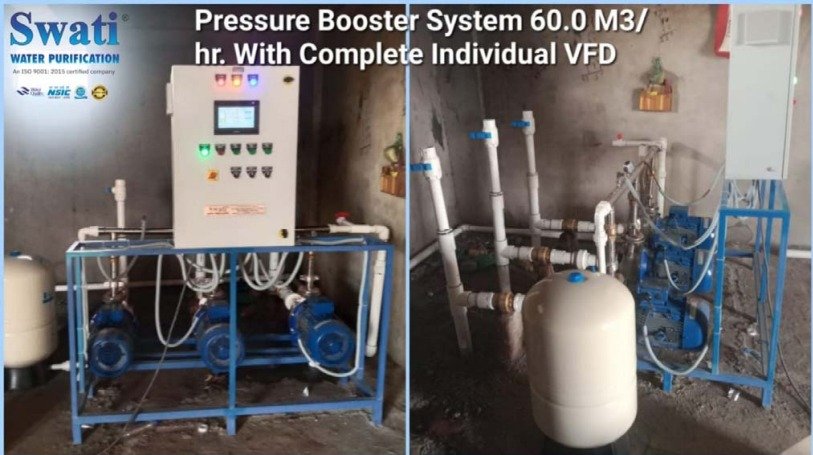

Pressure Booster System With VFD

Swati Water Purification – Pressure Booster System With VFD Supplier, Pressure Booster System With VFD Manufacturer.

Pressure Booster System With VFD

A Pressure Booster System With VFD (Variable Frequency Drive) is a Water Pumping System Used to Maintain Consist Water Pressure in a Building Or Facility, Especially When the Demand for Water Varies Throughout the Day. The System Consists of a Set Of Pumps, Pressure Sensors and a VFD to Adjust the Speed of the Pump Based on real-time Water Demand and System Pressure. The VFD Plays a Critical Role in Efficiently Controlling the Pump’s Motor Speed, Which in Turn Allows for Precise Pressure Control and Energy Savings.

Pressure Booster System With VFD (Variable Frequency Drive) Manufacturer

These Systems are Also Known by Different Names Depending on the Specific Application or Manufacturer. Here are Some Alternative Names for Pressure Booster Systems With VFDs: “VFD-Driven Booster Pumps,” “Variable Speed Pressure Booster Systems,” “VFD Pumping Systems,” “Pressure Boosting VFD Units,” “Dynamic Pressure Booster Systems,” “Smart Pressure Booster Systems,” “Frequency Controlled Pressure Systems,” “Variable Frequency Pump Systems,” “Flow and Pressure Control Systems,” “Automatic Pressure Boosting Units,” “VFD-Controlled Booster Stations,” “Energy-Efficient Booster Pumping Systems,” “Speed-Controlled Pressure Boosters,” “Electronic Pressure Boosters,” “Intelligent Pumping Systems.”

We Are Manufacturers & Suppliers In Ahmedabad, Gandhinagar, Gujarat, India, Sanand GIDC, Mehsana, Vitthalapur, Mandal Bechraji Special Investment Region(MBSIR), Halol GIDC, Bavla Kerala GIDC, Dahej SIR & PCPIR(Petroleum, Chemicals and Petrochemicals Investment Region), Dholera SIR, GIDC Industrial Area(Gujarat Industrial Development Corporation), MIDC Industrial Area(Maharashtra Industrial Development Corporation), MPIDC Industrial Area(Madhya Pradesh Industrial Development Corporation), RIICO Industrial Area(Rajasthan State Industrial Development & Investment Corporation), PSIDC(Punjab State Industrial Development Corporation), SEZs Area(Special Economic Zones), SEEZ Area(Solar Energy Enterprises Zone) In Rajasthan, Peenya Industrial Area In Bengaluru(Bengalore,Karnataka) etc..

How a Pressure Booster System With VFD Works:

1. Pumps: The System Includes One Or More Pumps that are Responsible for Pressurizing the Water and Maintaining the Desired Pressure Level in the Distribution System. These Pumps are Often Centrifugal Pumps Designed to Handle Varying Flow rates.

2. VFD (Variable Frequency Drive): The VFD is a Type Of Motor Controller that Adjusts the Speed of the Pump Motor by Controlling the Frequency and Voltage Supplied to the Motor. By varying the Speed of the Pump, the VFD Allows the System to Maintain the Desired Pressure without Over-Pumping, Which Reduces Energy Consumption. When Water Demand Increases (For Example, When More Faucets Or Showers are Turned On), the VFD Increases the Pump Speed to meet the Demand. Conversely, When Water Demand Decreases, the VFD Reduces the Pump Speed, thus saving Energy and Preventing Water Pressure from Exceeding Necessary Levels.

3. Pressure Sensors: Pressure Sensors Continuously Monitor the Water Pressure in the System. The Readings From the Pressure Sensors are Fed back to the VFD, Which Adjusts the Pump Speed Accordingly to Maintain the Pressure Within the Desired Set Point.

4. Control Panel: The System is Typically Controlled Via a Central Control Panel that Allows Operates to Set and Monitor the Parameters of the System, Such as the Desired Pressure Set point, the Max. Allowable Pressure and the Operational limits for pumps.

5. Storage Tank (Optional): Some Booster Systems may Include a Pressure Tank Or a Storage Tank. The Tank Can Store Water a Pressurized State, So When the Demand Fluctuates, the Pump Doesn’t Need to Work as hard. This helps Reduce Wear and Tear on the Pump and Provided a Buffer for Fluctuations in Water Demand.

Capacities Of Pressure Booster Systems With VFDs, Categorized by Different Applications:

1. Residential Pressure Booster Systems:

- Capacity Range: These Systems Handle flow rates from 0.5 to 5 Gallons Per Minute(GPM) or 1.9 to 19 Liters Per Minute (LPM)

- Pressure Range: Usually Operates between 30 to 80 psi (Pounds Per Square inch) or 2.07 to 5.5 bar.

- Application: Domestic Water Supply, Small Multi-Story Buildings, and Residential Complexes Where Maintaining Consistent Water Pressure is Crucial.

2. Commercial Pressure Booster Systems:

- Capacity Range: These Systems Can Handle Larger Flow Rates, Typically between 5 to 100 GPM(18.9 to 378 LPM), Depending on the Building’s Needs.

- Pressure Range: Pressures Generally Range From 40 to 150 psi (2.76 to 10.34 bar)

- Applications: Hotels, Shopping malls, Office Buildings and Medium-Sized Commercial Complexes.

3. Industrial Pressure Booster Systems:

- Capacity Range: Industrial Systems Can Handle Much Higher Flow Rates, Ranging From 100 to 1000 GPM (378 to 3,785 LPM) Or More.

- Pressure Range: Industrial Systems Can Operate at Pressures Ranging From 50 to 200 psi (3.44 to 13.79 bar)

- Applications: Manufacturing Plants, Industrial Facilities, Cooling Systems.

4. Large-Scale Or High-Capacity Pressure Booster Systems:

- Capacity Range: For Very Large Systems, Flow rates Can Exceed 1,000 GPM (3,785 LPM), Depending on the Application, With Some Systems Handling Upto 10,000 GPM (37,850 LPM) Or More In Extreme Cases.

- Pressure Range: High-Capacity Systems Can Provide Pressures Up to 400 psi (27.58 bar) Or More, Depending on the Design.

- Applications: Large Industrial Complexes, Municipal Water Supply, District Heating and Cooling Systems.